Plant Engineering

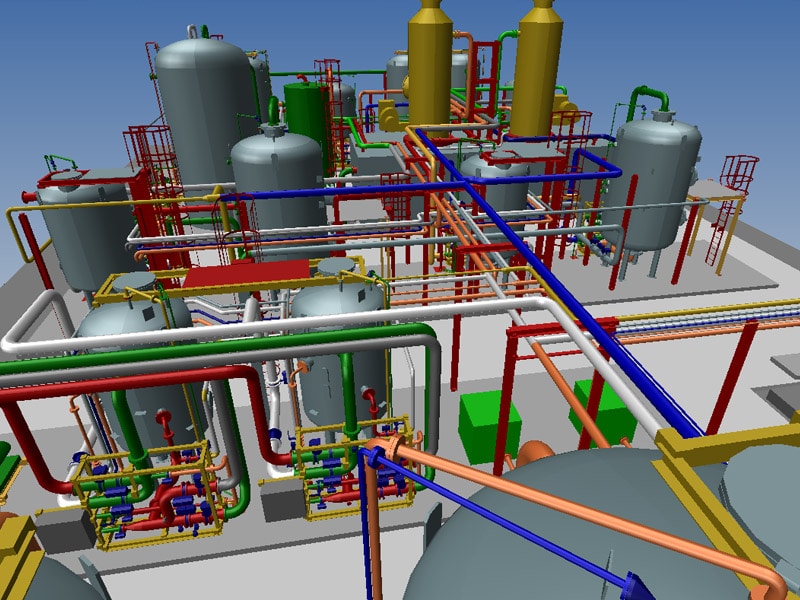

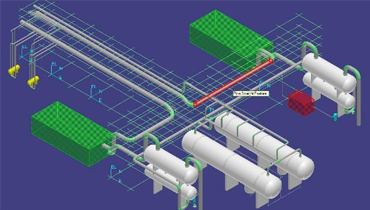

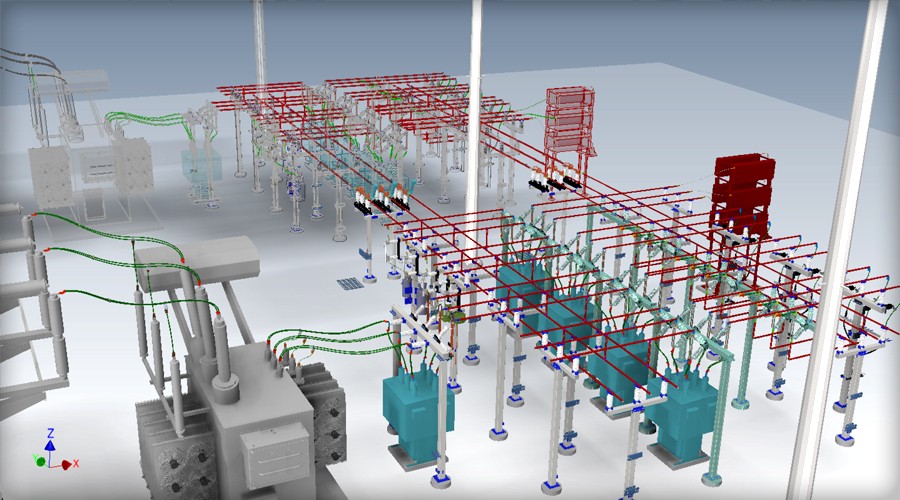

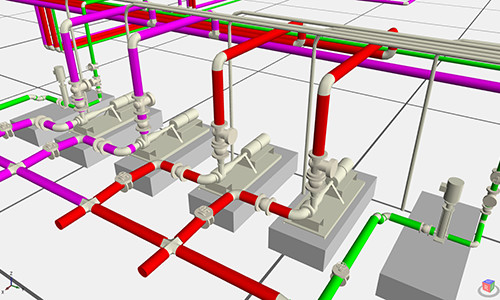

DDS team specialized in Mechanical, piping, instrumentation, electrical, civil, Structural and Process design department offers design and detail engineering services for the oil and gas plants, refinery, petrochemical, chemical, offshore, power plant, utility, process plants, air separation plants, fertilizer plants, steel plants, cement plants, pharmaceutical industries, water & wastewater treatment, and infrastructure facilities.

DDS engineers have expertise in related activities such as review of design criteria, review of contractor design documents and drawings, and project coordination. We are experienced in the use of a variety of supporting software including SmartPlant 3D, PDS, PDMS, E3D, CADWorx, AutoPlant 3D, AutoCAD, MicroStation, SmartPlant Review, NavisWorks, CAESAR II, Pelican Forge – Support Modeler, PV Elite, COMPRESS, TANK, STAAD.Pro, Tekla Structures, Revit Architecture, and Intergraph’s PDS FrameWorks Plus for modeling, SmartPlant Instrumentation (INtools), SmartPlant Electrical.

DDS Team of Engineers and Drafters With Vast Experience Enables Us To Deliver Industry Specific Services.

Get the Maximum Benefit with Our Customized Project Process as per Your Requirements. We are equipped with Infrastructure and Cutting Edge Technology Including Sufficient Bandwidth, Which is Compatible With the Requirements.”

Our Expertise Services

PROCESS

- Development of P&ID’s based on FEED

- Preparation of P&ID’s for utilities

- Preparation of plant operation and maintenance manual

- Preparation of line list, equipment list, valve list, etc.

- Hydraulic calculations

- Sizing calculations

- Performing insulation and heat tracing calculations

piping

- 3D model project set-up

- Piping material specifications

- Piping studies

- Painting and insulation specification

- Site survey / tie-in sketches Single line structure drawings

- Piping general arrangement drawings

- Isometrics

- Piping material take-off

- Support material take-off

- Insulation and painting take-off

- Updating key plans

- Equipment modeling

- Updating plot plans and unit plot plans

- Modeling of lines

- Nozzle orientation drawings

- Interface with other disciplines

- Pipe supports

- Stress analysis

- Requisitions

- Tracing / jacketing.

- Clash checking

- Model reviews

Mechanical

- Preparation of general arrangement drawings

- General arrangement drawings Duct fabrication drawings

- Design of ducts according to SMACNA

- DW standards

- Duct support drawings

- Detailed manufacturing drawings

- Final mechanical design verification of compliance with international codes

- HVAC, Mechanical data sheet preparation

- Providing civil loading details for equipment

- Technical clarifications during contract finalization

- Heat load calculations

- Strength calculations by using in-house programs /PV ELITE / COMPRESS, Design / selection of equipment

- Specifications for raw materials

- Strength calculations by using in-house programs /PV ELITE / COMPRESS, Design / selection of equipment

- Preparation of bill of materials

- Purchase specifications for brought out items and Material take off

- Design department delivers design and detail engineering of static and rotating equipment, packages, and HVAC

- Design department delivers design and detail engineering of static equipment including pressure vessels, shell and tube heat exchangers, towers, reactors, condensers, and evaporators as well as rotating equipment such as pumps and compressors.

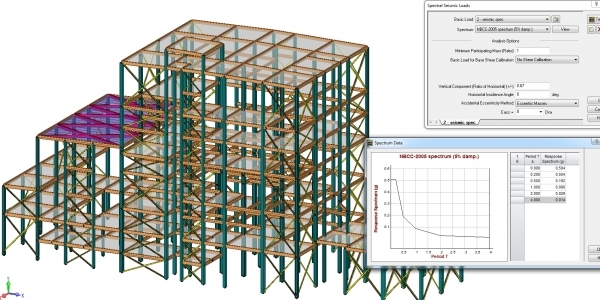

Structural

- Preparation of project specification,

- Preparation of design basis

- Pipe and cable rack structures

- Conveyor galleries

- Trestles

- Stack supporting structures

- Platforms

- Steel framed buildings and superstructures

- Switch yards, transmission line towers

- Large diameter / size storage sheds

- Turbine houses and workshop buildings

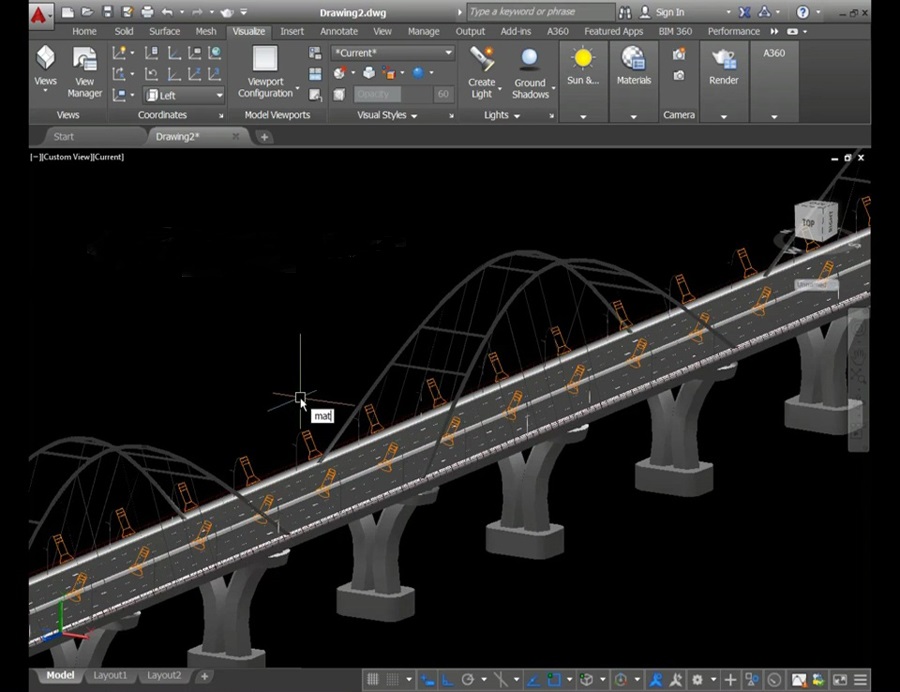

CIVIL

- Preparation of project specification,

- Preparation of design basis

- Pile and conventional foundations

- Reinforced concrete framed structures

- Equipment and machinery foundations

- Concrete storage silos

- Large diameter storage tank foundations

- Roads

- Pavement

- Grading plans

- Drainage systems

- Cable and Pipe trenches

- Retaining

- Dyke

- Boundary walls and Gates

- Tunnels

- Compound walls and Fencing

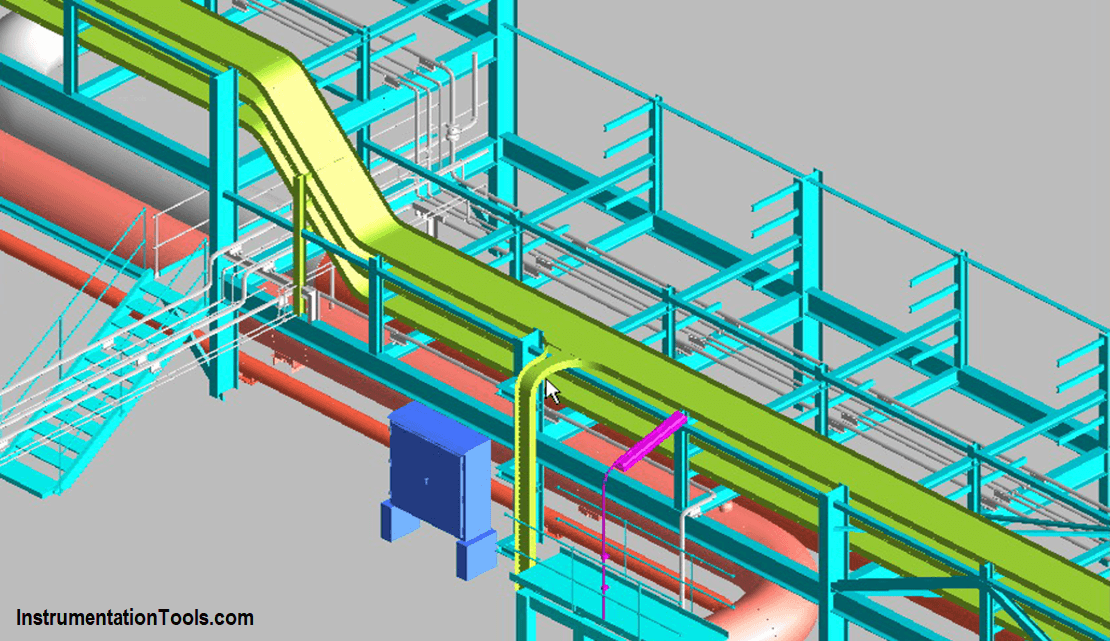

INSTRUMENTATION

- Preparation of project specification,

- Preparation of design basis

- Instrument index

- Detailed execution drawings

- Control philosophy

- Instrument elevation plan

- Cable tray / cable trench layouts

- Junction box termination drawings

- Interlock logic diagrams

- Instrument hook up drawings

- Cause and effect drawings

- Fire and gas drawings,

- Cable schedules

- Interface drawings for DCS, PLC, SCADA and MCC

- Earthing layouts for system and field

- Requisition and specifications for instruments,

- Scope of work for construction activities

- Sizing of control valves, orifice plates, and relief valves

- FAT and SAT procedures, Preparation of as -built drawings and documentation

- Review of vendor package systems.

ELECTRICAL

- Project specification,

- Preparation of design basis

- Load flow studies,

- Designing supply change over schemes for incomers and outgoing feeder control schemes

- Requisition / specifications for HV / LV switchgear, motor and control centre

- Requisition / specifications for MV / LV motors, power / distribution transformers, lighting / small power distribution boards and AC / DC UPS

- Requisition / specifications for lighting fixtures, power / control cables, cable trays and earthing materials

- Battery room layouts

- Cable routing layouts

- Earthing layouts

- Cable tray / trench layouts

- Lightning protection layouts

- Lighting (indoor / outdoor) layouts

- SCADA I / O list, Power and control cable schedules

- Interface activities with civil / machinery / instrumentation, Selection of feeder / motor / transformer protection relays

- Selection of power / distribution transformers

- Selection of HV / LV switchgear

- Motor control Centres

- Switchyard / transformer layouts

- Switchgear / MCC room layout

- Selection of AC / DC UPS

- Matching with civil for floor openings

- Electrical equipment foundation and

- Plants- Electrical data input for packaged equipment

- Standard installation drawings for power system

- Standard installation drawings for earthing system

- Standard installation drawings for lighting system and cable tray / ladders

- Review vendor drawings and issue approvals for manufacturing

- As-built project drawings / documentation.